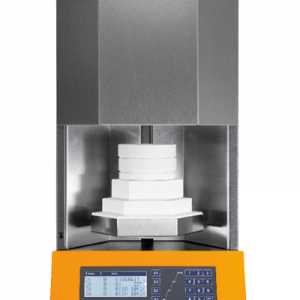

Description

It defines new quality standards in wet machining of blocks. In addition to restorations of glassceramics, PMMA, zirconium oxide and composite

s, also prefabricated titanium abutments can be finished with the highest precision.

FEATURE

Highest precision

- milling and grinding in ultra HD

- heavy industrial quality

- 3 microns repetition accuracy

Fastest production

- restorations in under 10 minutes

- 2-second block insertion

- 100,000 RPM electrical high frequency spindle

Extremely economical

- clear water – no additives necessary

- automatic changer for 6 tools

- self-opening working chamber door and drawer

- easy to learn, easy to operate

- 24-month warranty

Complete independence

- 38 block materials from 20 manufacturers – and growing

- >190 titanium prefab abutments from 11 manufacturers

- validated with all established scanners and design software

- fully integrated workflow with TRIOS Design Studio (3Shape), DWOS chairside (Dental Wings) and exocad ChairsideCAD

- Integrated PC with touch screen and Wi-Fi – no laptop or tablet necessary

- Built-in compressed air – no compressor needed