Description

-

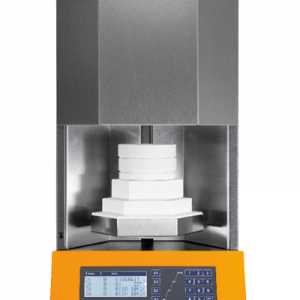

Operating the machine is also incredibly simple thanks to various patent-pending technologies: With DirectDiscTechnology, milling blanks can now be processed directly without any cumbersome fiddling with the tenter frames. Like all vhf machines, the R5 can be used with a maximum variety of materials from all manufacturers when it comes to discs, blocks and abutments and therefore provides perfect investment protection!

THE MULTI-TALENT FOR EVERY APPLICATION

-

DirectCleanTechnology allows you to conveniently switch between wet and dry machining. In addition to integrated ionizers and active workspace ventilation, the R5 also has a highly intelligent drying feature.

Another novelty is the integrated water cooling, which significantly minimizes the thermal expansion of the spindle and Z axis. Faster machining with even more consistent results and longer spindle lives are the benefits for future R5 owners.

The ability to feed milling blanks up to 40 mm thickness via a blank changer and get right to work is another highlight. Even better is the generous tilt angle for the fifth axis of ± 35 degrees. The R5 thereby guarantees a maximum of indication variety and freedom of design.

FEATURES

– Maximum Precision

- restorations in ultra HD

- water-cooled high-precision spindle

- 3 microns repetition accuracy

– Powerful Robustness

- mills and grinds the toughest materials on the market including all Ti and CoCr

- 800 watts of power and 80,000 RPM

- heavy industrial quality

– Absolute Independence

- sheer unlimited material accessibility in 98 mm disc format, 30 block materials, and > 140 titanium and CoCr prefab abutment platforms

- covers the broadest range of indications, due to ± 35° rotation angle in the 5th axis, and up to 40 mm blanks

– Highly Economical

- one of the fastest machines on the market

- revolutionary material loading with DirectDiscTechnology (patent pending)

- automatic changer holds up to 10 discs, 60 blocks, or 60 prefab abutment blanks

- DirectCleanTechnology enables wet and dry on the fly: ionizer, self-cleaning and built-in dryer (patent pending)

– Unmatched Reliability

- 100 percent engineered and manufactured in Germany

- comprehensive sensor technology to monitor all vital system functions

- webcam for remote monitoring

- 24-month warranty