Description

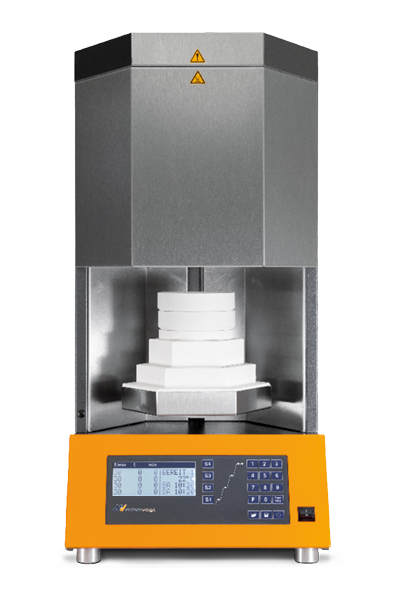

The redesigned HTS-2 model series combines the well-known features of previous models.

The simple, practical handling of the HT-series program control was also incorporated here with all its familiar functions; program display on a four-line LCD-display, timer function for sintering overnight or also using drying programs for wet-milled restorations. There are three service programs for servicing the heating chamber and the heating system.

| Technical information | HTS-2/M/Zirkon-120 |

|---|---|

| Power max. | 3200 W |

| Voltage range / frequency | 200-240 V / 50-60 Hz |

| Weight | 60 kg |

| Dimensions W/D/H | 390/500/790 mm |

| Process capability |  |

| Max. temperature |  |

| Heating elements |  |

| Number of heating elements | 4 |

| Heating-chamber height | 72 mm |

| Max. heating-chamber capacity |  120/30mm |

HTS-2/M/ZIRKON-120

-

60 SINGLE CROWNS OR SINTERING DISC

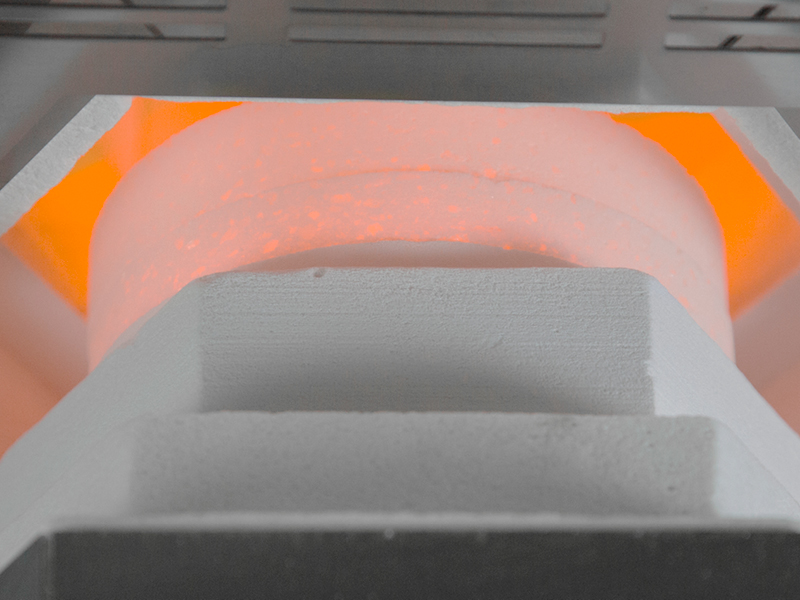

- High-quality molybdenum-disilicide heating elements PRO

- Maximum temperature 1650°C

- Heating-chamber capacity 2x Ø 120/30 mm

- Program control (LCD-Display, 4 stages, 30 program capacity, Special functions)

- Service programs

A - Temperature control*

only in conjunction with test-kit

C-Purge heating chamber

E- Regenerate heating elements - Thermocouple PtRh-Pt, type S

- Temperature accuracy at 1500°C +/- 3°C

- Timer function