Description

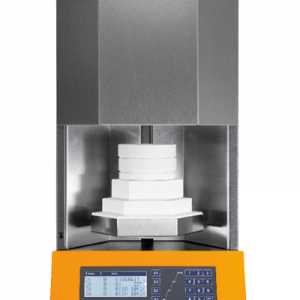

TABEO offers you the possibility to decide whether to use heating systems with heating elements made of MoSi2 or SiC. Both systems are designed for conventional long-term sintering. Heating elements made of molybdenum disilicide (MoSi2) offer a maximum furnace temperature of 1650°C. With the pre-defined service programs, contaminations on the heating elements can be regenerated.

Due to their physical properties, heating elements made of silicon carbide (SiC) offer a maximum furnace temperature of 1550°C. The SiC heating elements do not need to be regenerated with a service program.

| Technical information | TABEO-1/M/ZIRKON-100 | TABEO-2/M/ZIRKON-120 | TABEO-1/S/ZIRKON-100 | TABEO-2/S/ZIRKON-120 |

|---|---|---|---|---|

| Power max. | 1500 W | 1800 W | 1700 W | 2000 W |

| Voltage range / frequency | 220-240 V / 50-60 Hz | 200-240 V / 50-60 Hz | 200-240 V / 50-60 Hz | 200-240 V / 50-60 Hz |

| Weight | 55 kg | 80 kg | 60 kg | 85 kg |

| Dimensions W/D/H | 400/400/600 mm | 480/460/680 mm | 400/400/600 mm | 480/460/680 mm |

| Process capability |  |

|

|

|

| Max. temperature |  |

|

|

|

| Heating elements |  |

|

|

|

| Number of heating elements | 4 | 4 | 4 | 4 |

| Heating-chamber height | 42 mm | 92 mm | 42 mm | 92 mm |

| Max. heating-chamber capacity |  100/30 mm |

120/30 mm |

100/30 mm |

120/30 mm |